Different types of plastics

Before we look at the best tools for cutting plastic, we first need to look at what plastics are, because to get the best results there isn’t a one tool fits all.

There are several different types of plastics available, all with a different make up and therefore different cutting needs and requirements.

For the purposes of cutting plastic, we have broken down this versatile material into three different categories:

- Hard plastics

- Soft Plastics

- Acrylic

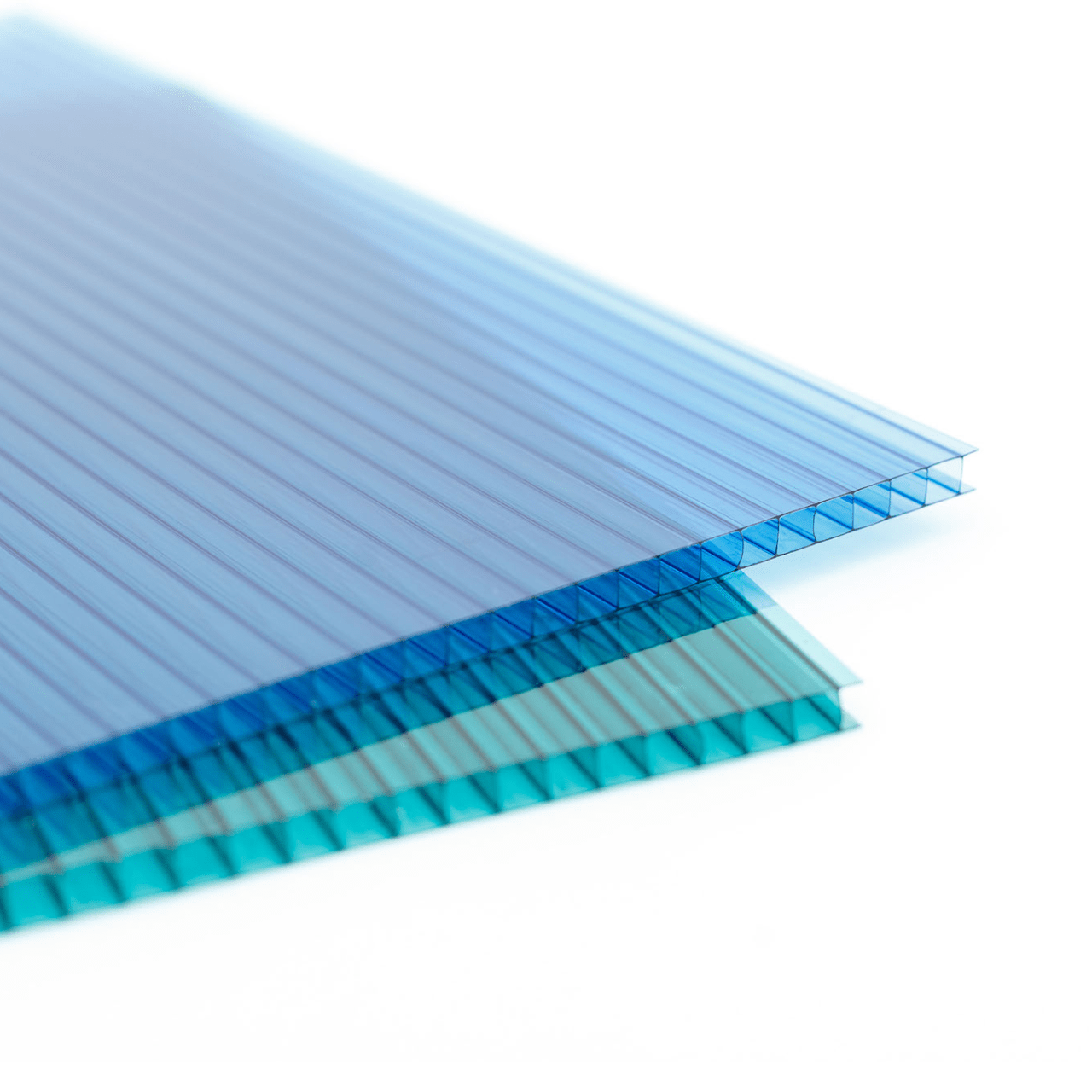

Hard plastics

Hard plastics such as polycarbonates and ABS are strong, tough and often transparent. They are ideal for glazing as they are stronger and much more thermally efficient than glass. Polycarbonates have a good heat resistance and can be combined with flame retardant materials without significant material degradation.

Popular uses: glazing, green houses, sunglasses, DVDs

Soft plastics

We deem it to be a soft plastic when the waste material comes off in spirals when being cut rather than chips as it would with a hard plastic or acrylic.

Popular uses: sign making

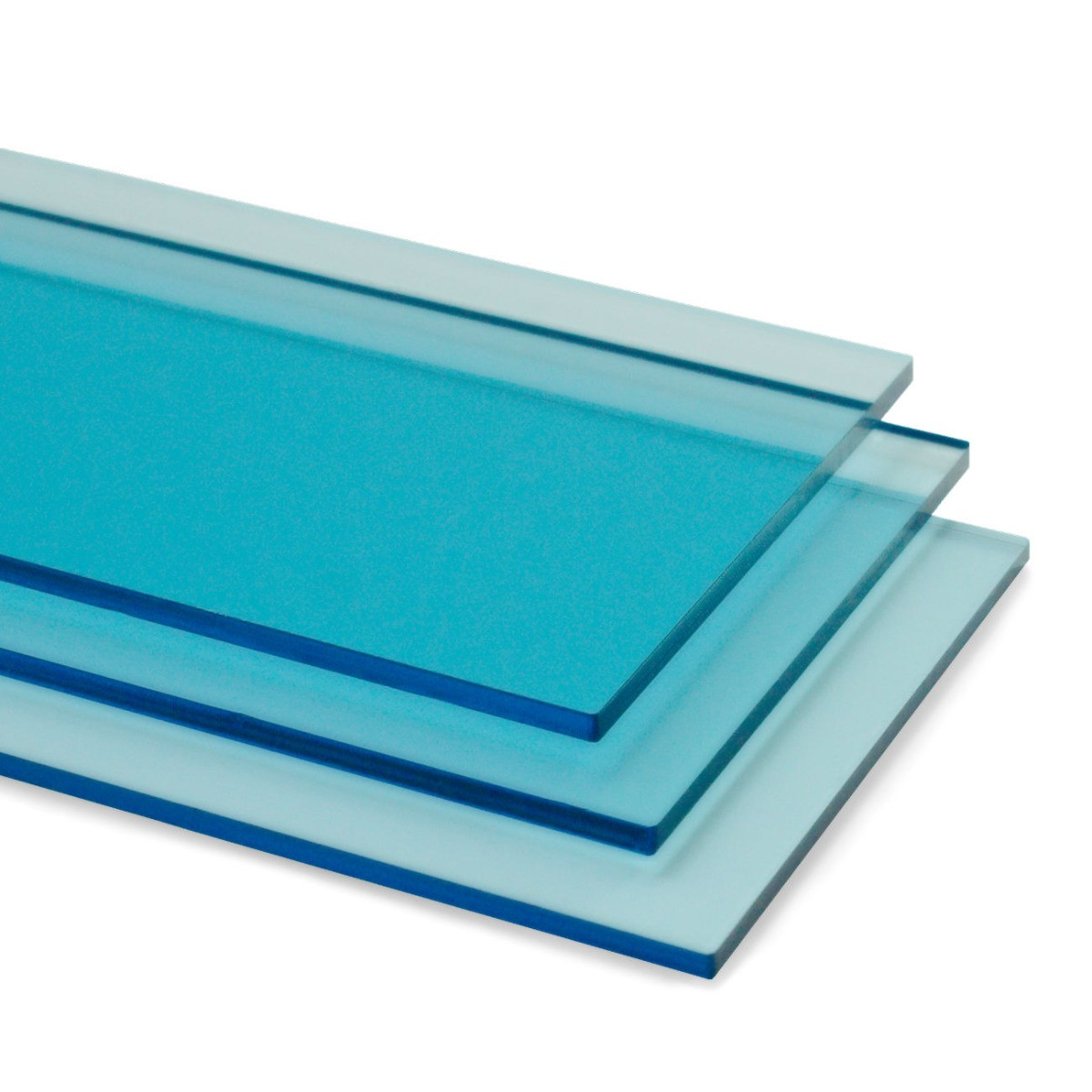

Acrylic

Acrylic is a great, durable and flexible material to work with. It is a great substitute for glass at half the weight and comes with an impressive impact resistance. Acrylic is available in every colour imaginable but is not recommended in areas close to extreme heat. Sheets of acrylic are also called Lucite, Optix and Plexiglass.

Popular uses: kitchen and bathroom splashbacks, retail stands, signage, as a safer, stronger, lighter and cheaper alternative to glass (picture frames, tables etc)

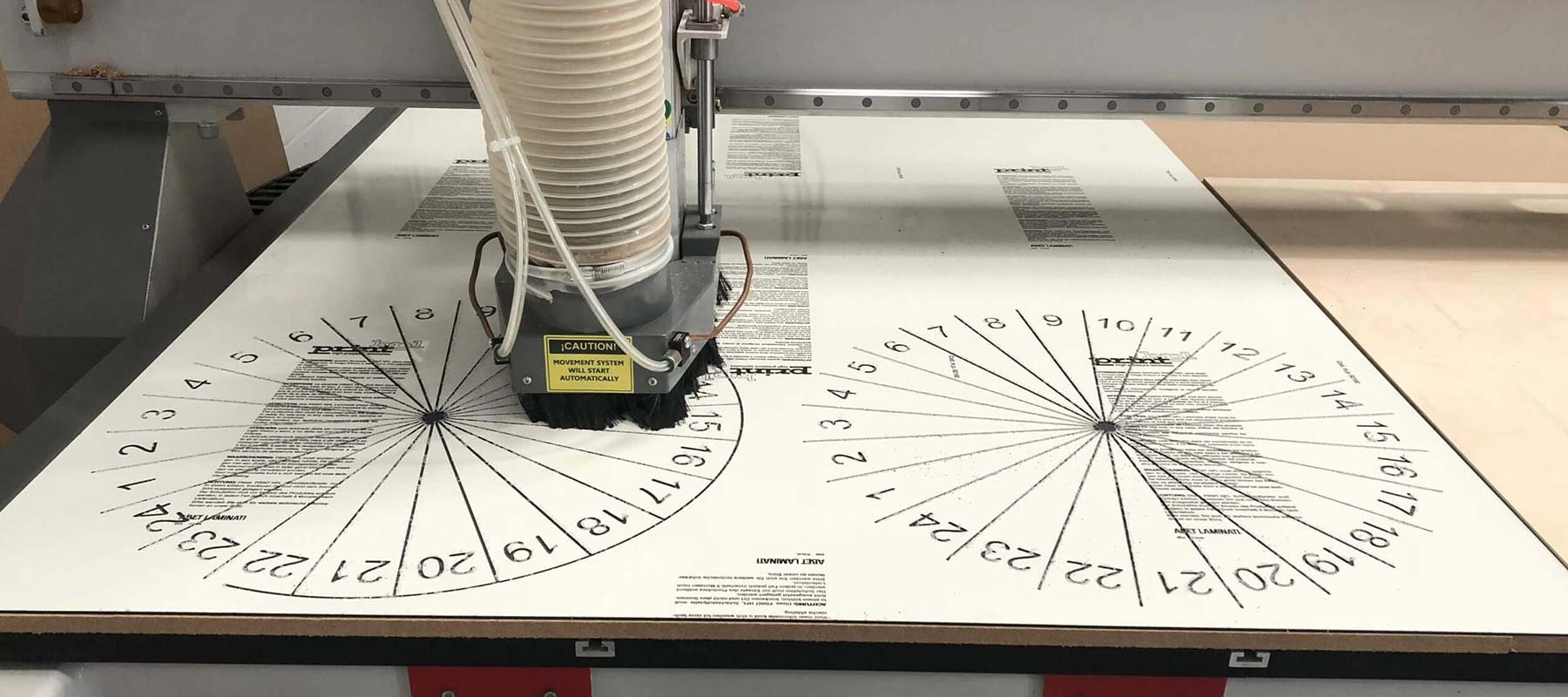

What is the best CNC router bit for plastic?

It may seem obvious to state but you will get the best results when cutting any material if you choose the appropriate router bit. Specific router bits are designed to work with the properties of specific materials, which offers the cleanest cuts and the best finish.

Tip: make sure you secure the plastic in place; excess vibration will lead to marring the finish and any movement could lead to an increased wastage in materials.

Acrylic cutter

A common problem when cutting acrylic on a CNC router is that the material heats up, meaning that the edges melt slightly and then reform either bonding back together or giving you a rough edge. To combat this, you will need to decrease the time the router bit and the acrylic are in contact, use our speeds and feeds calculator to help ensure that you get the best finish.

The two flute low helix tools, 4200 and 4300 series, are designed specifically for cutting acrylic, although they can be used for cutting other solid surfaces. Low helix tools are very sharp and produce less lifting from the router bed resulting in an excellent finish. The upward design ensures optimal chip removal which is key when cutting acrylic on a CNC router. We also recommend the 56X-198 Series and 57X-198 Series.

CNC plastic cutter

When it comes to cutting hard and soft plastics much of our advice is the same.

We would always recommend using solid carbide tools when cutting hard and soft plastics, although they are more expensive if appropriately used, they will last longer and give a better finish due to the shapes and geometry of the cutters. Polished flute cutters give better chip removal and therefore extend the life of your tools. We recommend using the 56X-198 Series and 57X-198 Series.

View our range of CNC router tool bits for cutting hard plastic and soft plastic.

If something isn’t going to plan, please give one of our friendly technical team a call who will be able to offer advice on achieving the best finish.