What is Corian?

Developed in 1967 by scientists at Du-Pont, Corian has become a firm material favourite when it comes to designing work surfaces and splashbacks because of it’s strength and durability.

An engineered stone like material, similar to Quartz, Corian is made from a mix of 1/3 acrylic resin, 2/3 natural minerals and a little colour to achieve the desired look. When these materials are mixed together it makes a hardy substance, ideal for the kitchen or bathroom.

Once the acrylic resin has set it creates a tough outer shell which can withstand daily knocks as well as hold a lot of weight. Corian is also non porous meaning that spillages will not penetrate the material* adding to the reasons why it is becoming so popular. *As a note stains should always be cleared up as soon as possible to prevent markings.

Which tools are best for cutting Corian?

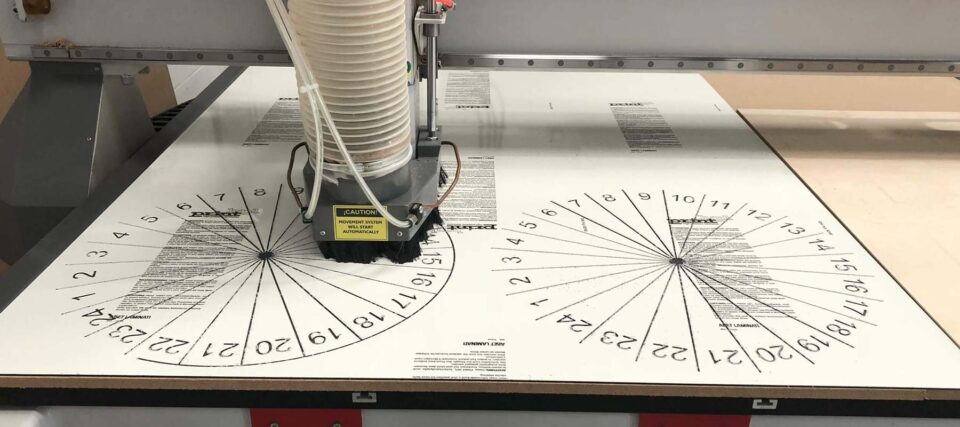

Du-Pont stress that router bits should be at least tipped with Tungsten carbide however we recommend a Solid Carbide Single O flute Upcut Spiral Tool as the upcut spiral allows for greater chip removal . Tools made from solid carbide offer a smoother finish.

Corian is comparable to granite in price so although you can use several different types of saw and blade you will not get the same clean finish as using a CNC router partnered with the specific tools designed to cut solid surfaces. Using the recommended tools will mean less chance of a break out and less chance of marking the Corian.

Look out for the correct size of tool to match the thickness of the solid surface you intend to cut.

Safety

As a note you should always wear a mask and protective eye wear when cutting Corian because the dust created can irritate the lungs and eyes.

Conclusion

Corian is both practical and functional whilst being an easy material to work with, although due to it’s cost it’s a material you don’t want to make too many mistakes with. When cutting Corian and to achieve the best finish we would recommend using a router along with solid carbide tool.

*Image credit: Corian.co.uk