Wood working is one of the oldest vocations with many hand tools almost the same now as they were a thousand years ago. The ancient Egyptians created intricately decorated furniture and musical instruments and the Romans took great pride in their wood work.

Wood is one of the most versatile materials to work with and is readily available so it makes sense that there would be several options for cutting, shaping, carving and manipulating it to become a part or product for sale. Kitchen cabinets, skirting board, decking, cutlery, signage to name a few.

There are several different options when it comes to cutting wood. Wood cutters cover a wide range of tooling, offer different qualities of finish and can be everything from hand held devices such as saws through to industrial scale CNC routing machines. We discuss below the differences and benefits of each below.

Hand tools

We couldn’t not mention the role that the simple saw plays when cutting wood. But hand held wood cutters are wide and varied both in their role, ability and price range.

It is fair to say that although our business is concentrated around router tooling bits for CNC machines there are times when working with wood by hand can be beneficial.

- On a basic level saws are ideal if you are creating a garden structure or cutting down a tree and they are readily available at DIY stores

- Working with wood by hand can also give you a different finish each time, offering a more authentic hand made or bespoke finish which can demand a higher retail price tag

- Hand tools create certain affects and unique marks

- There are no loud noises

- Although handheld tools can vary in price they are cheaper than buying your own router

- You may need less space than if you have power tools or a router

Routers

A router is a powerful tool used to cut, engrave and shape various materials including wood, offering a professional smooth finish. You can buy different tool bits to fit into the router which allow you to cut different types of material and create different effects.

There are two main differences when discussing routers, handheld and CNC. Although with everything once you delve deeper you will find the cut and finish quality as well as the machines capability is vastly different so always do your research.

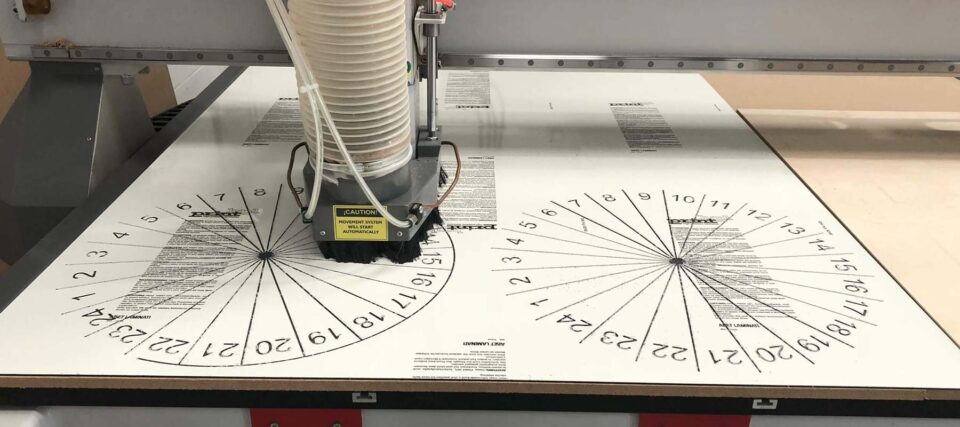

CNC stands for Computer Numerical Control. A CNC machine is one which is controlled by a computer to cut or engrave shapes in several different materials. CAD software is used to program the CNC router to take an image and turn it into a finished part or product.

The benefits of a hand held router

- The cost of a hand held router is cheaper than a CNC router

- Very large sheets of material may not be able to be fully supported on a CNC router table and therefore a hand held router would be best

- Easier to make adjustments mid way through a job if needed

- When it comes to delicate carving or engraving a hand held router can be easily manipulated for intricate movements

- Readily available online and in DIY stores

The benefits of a CNC router

- You can program the machine to cut exactly the same part or product time and time again at a speed not matched by human hand

- A CNC Machine achieves a consistent product every time offering flawless repeatability

- The machine can work over a large sheet of material without having to readjust the material, minimising mistakes and wasted materials

- Many routers will calibrate the depths and cutting speeds of materials

- Automatic tool changers mean that even with the need for different wood cutting tools you can set the job up and the machine will change the tools when needed

- The speed at which a CNC router can cut

- Accuracy – there isn’t a more precise tool when it comes to working with wood, meaning that material costs are kept to a minimum

As a note many large CNC machines are built to order so it is important to speak to the supplier or manufacturer if you need a new machine urgently as they may hold stock or have second hand machines available. For more information on CNC Routers speak to our sister company, CNC World.

Conclusion

Whilst there are several types of wood cutters available, the tool you choose should ultimately be chosen by what the desired finish is and the type or product you want to create.

Information about the different types of cutting tools and router bits available can be found here on our website, however if you have any questions please give our team a call on 01329 246070.