What is Aluminium?

Silver in colour, Aluminium is a light weight metal and is the most widespread metal on earth. It has a lower density than many other common metals making it easy to form and machine.

What is it used for?

Aluminium has a wide variety of uses from foil used in the kitchen, due to its moisture resistance, keeping food from going dry to parts for an aeroplane due to its excellent corrosion resistance. Aluminium is also a good electrical conductor and much cheaper than copper so is now commonly used in electrical transmission lines.

Aluminium Cutters

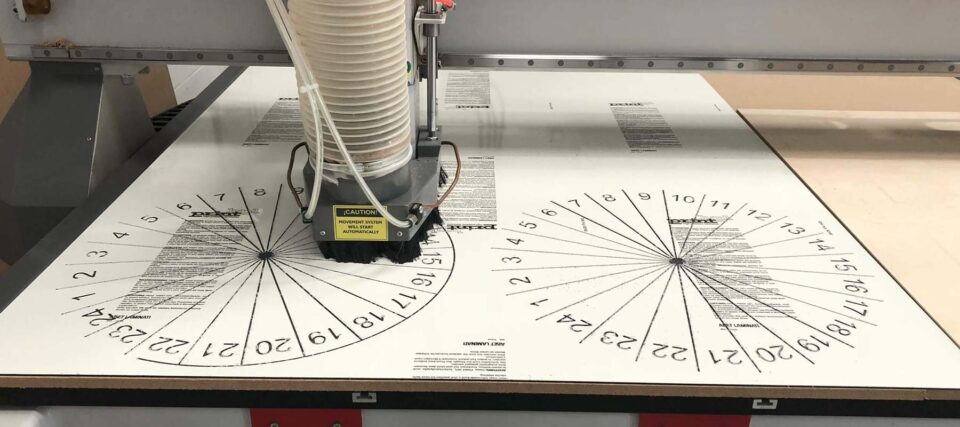

Aluminium can be cut on a range of machines from using a mitre saw to Milling Machines up to CNC Plasma machines. With a CNC Routers it’s possible to have one cost effective machine to cut a wide variety of materials from acrylic to aluminium, so we will be focusing on the best CNC router cutting tools for cutting Aluminium.

We say it a lot but you will always get the best result when using the appropriate tool. There are a lot of router bits which won’t give you a great finish or will break easily when it comes to cutting aluminium. By choosing the appropriate router tool, and calculating the best feeds and speeds, cutting aluminium should be easy.

As with all materials it’s not just the material that needs to be considered but several other factors which can be the difference between a great cut or a messy one. These include the thickness of the material, the depth of cut and the finish you are after – if you’re working with a material for the first time our friendly customer services team are on hand to answer any questions.

When it comes to aluminium there is more than one type, sheet and plate are the most commonly used:-

- Aluminium sheet. We advise using a single flute CNC tool like the 5600A Series when cutting Aluminium sheet. It forces a slower cut ideal to the often thinner sheet, less contact with the material results in a better finish as you don’t build up as much heat and friction

- Aluminium plate. As a much harder material we advise using a two flute router tool like these Hemi Cutters. You can drive your two flute bit with higher feed rates than a single flute.

To lubricate or not?

When cutting Aluminium we would always advise using a lubricant. Using a lubricant helps to maintain a lower temperature as there is less friction resulting in a longer tool life

Things to watch for

Aluminium as with many metals have a smaller range or ‘sweet spot’ when it comes to speeds and feeds for cutting. This means for the longevity of your CNC router tools it’s good to use a feeds and speeds calculator or speak to an expert before you begin cutting.

Clear the chips away! Aluminium chips can easily clog up CNC router bits as they stick to the cutters. Using an upcut tool lifts the chips up and out of the cutting path and using a lubrication should stop the chips sticking to the tool.

The chips can also fly everywhere, when working with Aluminium please wear safety glasses and be prepared for the clean up afterwards!

If you have any questions about appropriate tools for the job please contact our customer services team on 01329 246 070.

*It’s always good to read your CNC machine manual before cutting a new material as there may be specific instructions, hints and tips on cutting various materials.